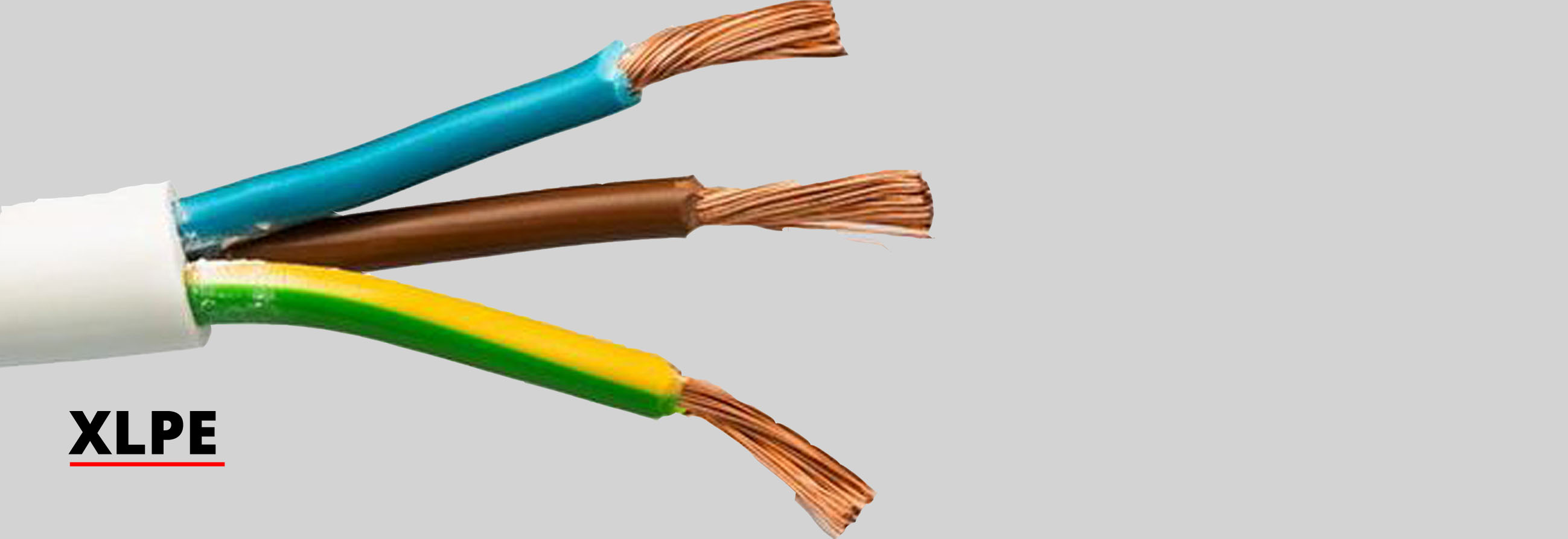

Cross-linked polyethylene (PEX or XLPE) has been around for quite some time. The first cross linking methods emerged in the 1930s and practices have continued to evolve since, with other processes being developed throughout the years. Cross linking is a very intricate process. XLPE raw material powder is formed and processed into sturdy, durable end products, usually formed into cylindrical shapes that can be used for long tubing. If during the cross linking process the degree is too high, the material could become brittle and cause stress cracking. If too low, the physical properties could be very poor and unusable. But made just right, the tubing can act as a strong, long-lasting insulator to various wire and cables, protecting it from all sorts of external elements.

Cross-linked polyethylene is often used for pipe and tubing in the plumbing industry. Probably the most common reason for using PEX is to replace traditional galvanized steel, copper and PVC piping due to rusting, cost and circulation. Cross-linking can solve plumbing issues at competitive pricing and can sometimes be easier to install. Cross-linked polyethylene can be useful in the electric industry too.

Important Benefits

There are many benefits to cross-linked polyethylene. Some include:

- Works with a variety of voltage ranges 600V to 35kV

- Provides mechanical protection

- Can withstand extreme pressure

- Resists underground damage

- Weather resistant

- Thermal resistance

- Permits high conductor operating temperatures

- Reduces short circuit and overload levels

- Is more cost effective than traditional solutions

- Flexible

- Moisture resistant

Datasheet |

| BCX 1230 &1331 |